Innovations

Cutting-Edge Technologies and Years of Experience

Since its inception in 1999, MRTS JSC has been operating under this principle. Over the years, the company has amassed extensive experience in pipeline installation and all kinds of subsea technical operations, even in the most challenging and extreme climates, including the Russian Far North. Collaborating closely with both domestic and international experts and research institutions, the company successfully implements the most innovative projects.

Today, MRTS JSC is fully equipped to undertake projects of any complexity and at various depths. Guided by a management policy focused on continual improvement, the company is committed to enhancing its technical capabilities and implementing new ideas and innovations to tackle the most ambitious projects.

THE ONLY ONE IN THE WORLD

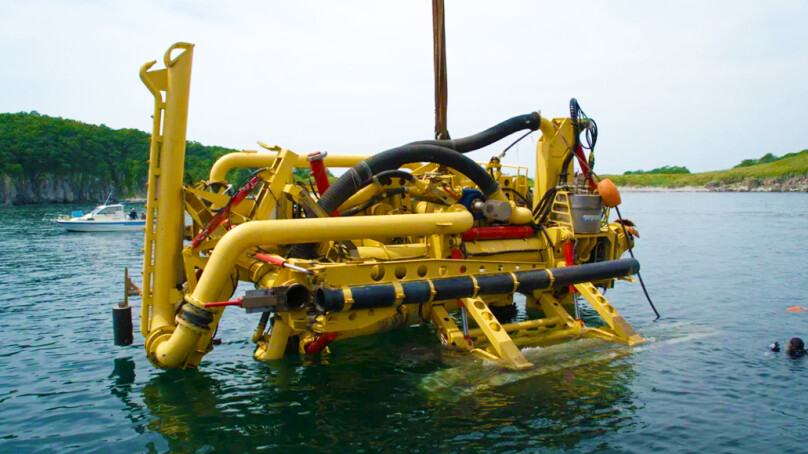

Our company actively integrates and pioneers innovations across diverse operational domains. A prime example is the custom-designed and built in a single copy self-propelled underwater trencher, the Arthropod 600, tailored exclusively to the needs and requirements of MRTS JSC.

The Arthropod 600 is a semi-autonomous technical system that moves along the seabed on caterpillar tracks and can operate at depths of up to 350 meters when controlled from a ship.

The unique design of the trencher allows for the efficient completion of tasks in record time and using minimal resources. This method of trenching subsea pipelines is more economical than using a dredge and more conventional methods.

Equipped with powerful milling cutters, the Arthropod 600 excavates the soil, creating a trench 2 meters wide and 3.5 meters deep for sinking of pre-laid pipeline. It is suitable to use for both preliminary and subsequent underwater trenching operations and can handle various types of seabed soils, from soft and loose to hard substrates.

Arthropod 600 is an innovative technology for digging underwater trenches, which easily adapts to existing soil conditions, ensuring optimal performance in any circumstances.

Technical Specifications

DEEP-WATER DIVING SYSTEM MGVK-300

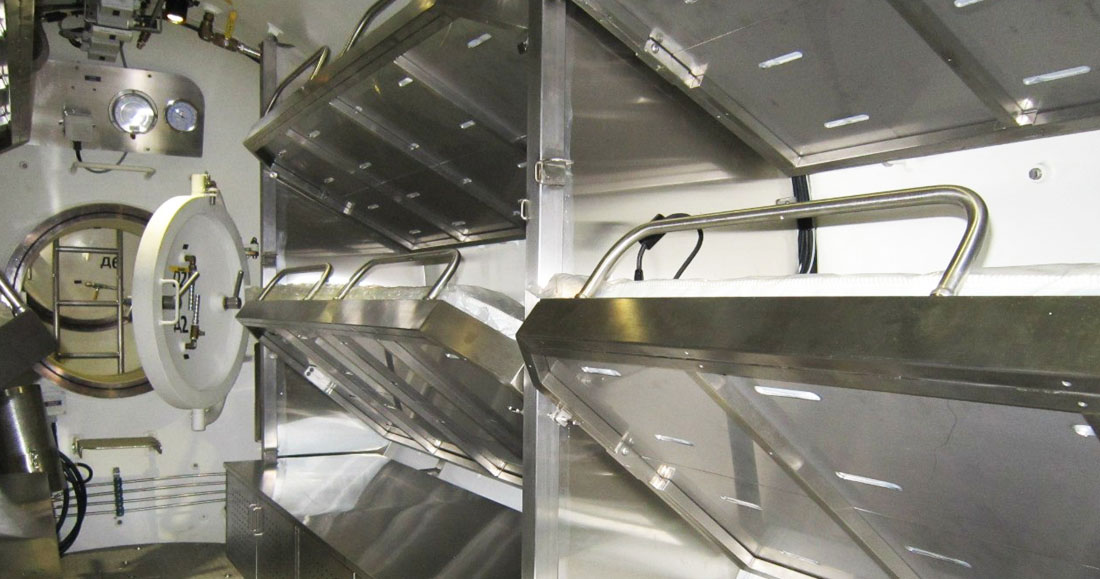

MGVK-300 is a complex engineering system that significantly affects the appearance of the carrier ship and its tactical and technical characteristics. The system includes two two-compartment living pressure chambers with thermal insulation for three and six people, respectively. Each chamber has a reception-and-exit compartment, where a bathroom and shower are located.

MGVK-300 is the first unique mobile deep-water diving system in the history of our country, installed on a carrier vessel of a domestic company.

A rescue evacuation single-compartment pressure chamber for nine people is docked to the system, designed to fit the entire team of divers who are under pressure. It serves as a guarantor of protection in possible force majeure situations: fire, power outage, flooding of the ship. If necessary, the evacuation chamber is thrown overboard (while remaining afloat), then towed and installed on another ship or on the shore. Then, a decompression process takes place in order to reintroduce the team to atmospheric pressure.

Technical Specifications

In intensive diving mode, the system enables 9 divers to work round-the-clock in three shifts at depths of up to 300 meters. The diving bell can also be used in an observation camera mode at depths of up to 200 meters.

Unlike the pressure chambers located on board the vessel, the diving bell is in motion. To descend to the object, divers move from the pressure chambers into the diving bell using the transition gate of the reception-and-exit compartment, where they put on their equipment before diving and take off their special suits after a dive.

Operating Conditions

The diving bell is equipped with an autonomous emergency ascent system from a depth of 300 meters, which, in the event of an accident or delay in ascent on board of the vessel, allows to sustain life of three people for 24 hours. The bell is lowered under water and raised to the surface using a lowering and lifting device (LLD). This is a complex technical system that neutralizes the effect of ship motion on the bell and ensures the safety of divers.

The MGVK-300 diving system meets with the requirements of the Russian Maritime Register of Shipping (RMRS), the American Bureau of Shipping (ABS), and the International Marine Contractors Association (IMCA).

DREDGING SYSTEM DAMEN TSP-650

Planned activities for the 2023 navigation year to develop a trench for an underwater passage across the Yenisei River have been completed. To carry out these activities, the dredging system Damen TSP-650 was installed on board the “Captain Bulganin” vessel, allowing for the excavation of soil at depths of up to 53 meters.

Installation of the system required extensive modernization of ship equipment and systems: soil retrieval device, hoisting system, dredging system’s control and positioning systems, hydraulic scouring system and soil delivery pipeline.

As a result of the modernization, the vessel successfully operated through the 2023 navigation year to develop trenches at specified depths and on various soils, including heavy ones (clay, stones, loam).

Taking into the account the achieved results, the vessel "Captain Bulganin" is scheduled to participate in the construction of the second line of passage across the Yenisei River during the 2024 navigation season.