Metal structures

The MRTS group of companies has the technical capability to implement the full cycle of production of metal structures.

Our advantages

- Closest to the Arctic production facility and logistics base;

- Manufacture of unique types of products;

- Own port structure;

- Year-round port operation;

- Direct access from the M-8 highway and railway (without bridges and river crossings);

- Developed infrastructure of the region and surrounding areas.

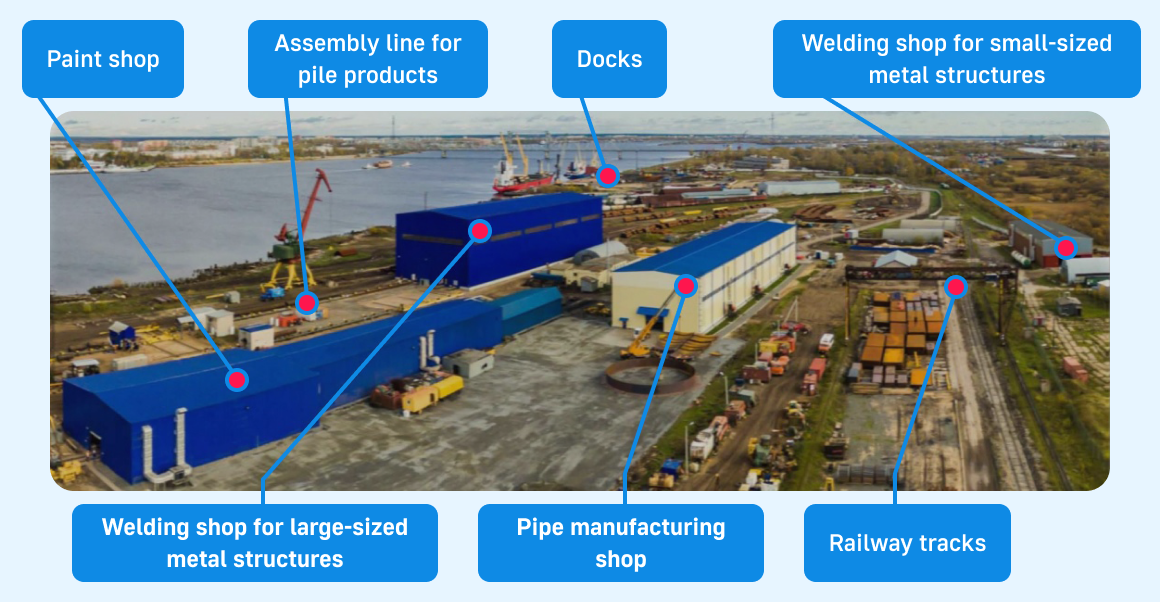

Production Structure

Pipe Production Shop

This production department is designed to manufacture pipe products ranging in diameter from 820 to 2,500 mm with the wall thickness of up to 45 mm.

Technological Equipment:

- Welding equipment HAANE (Germany);

- • Bending equipment DAVI (Italy).

Example of Unique Product

Manufacturing of metal structures for the Automated Wireless Observer Unit tower

Welding Shop

The shop is designed for the manufacture of medium-sized and small-sized construction metal structures of various structural purposes.

Shop Dimensions: 70×20,5×11,5 meters.

Capacity:

- 1,500 tons per month (small-sized construction metal structures);

- 1,500 tons per month (medium-sized construction metal structures).

Technological Equipment (short list):

- Gas cutting machine SAPPHIRE BL2;

- Portal plasma cutting machine MicroStep;

- Abrasive cutting machine - 400 B;

- Vertical drilling machine 2n135 (2 units);

- Screw cutting engine lathe 16 k20;

- Bandsaw machine Stalex TGK-4240;

- Welding machine FastMig F 450 (35 units);

- Pipe bending machine UG S-6/1A.

Example of Unique Product

Manufacturing of metal structures of large diameter shells

Assembly and Welding shop for large-sized metal structures

This shop is designed for the manufacture of pile products with diameters ranging from 116 to 2,520 mm.

Painting shop (stationary)

The shop's productivity is up to 2,000 square meters per day.

Technological Equipment:

- Transport modules 25 tons (12 units);

- Rotational modules (24 units);

- Airless spray painting machines Graco (22 units);

- Jet cleaning machines (16 units);

- Compressor equipment (12 units).

Painting shops (Mobile)

The assembly of structures is carried out both in the production base and on the construction site (assembly time is 70 days).

The productivity of the shops is up to 400 m2/day.

The shops are equipped with all necessary technological equipment (heating, ventilation, fire alarm, transportation and crane equipment, painting and abrasive blasting equipment).

Size of the produced pile products:

- Length - up to 24,000 mm;

- Diameter - up to 2,500 mm.